855 605 4599

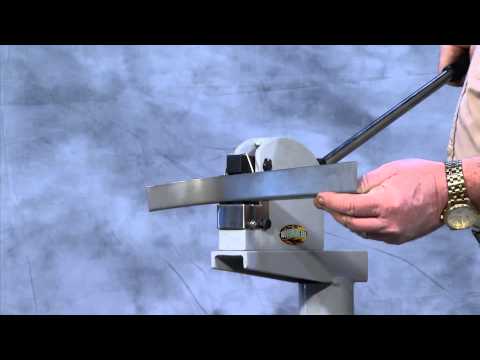

Shrinker Stretchers

Sheet Metal Shaping Made Easy with Our Industrial-Grade Shrinkers and Stretchers

Filters

Woodward-Fab WFSSHD2 Heavy Duty Foot Operated Shrinker Stretcher

Woodward-FabWoodward-Fab WFSSHD2 - 8-inch throat depth Shrink and Stretch The WFSSHD2 from Woodward-Fab is a heavy duty, foot operated shrinker stretcher that ...

View full detailsEastwood Elite Deep Jaw Metal Shrinker Stretcher (21489)

EastwoodShrink and Stretch Deep Into Panels with the Eastwood Elite Deep Jaw Shrinker Stretcher With a 7" throat depth and capacity for up to 16ga mild ste...

View full detailsWoodward-Fab WFSS14 Heavy Duty Foot Operated Shrinker Stretcher

Woodward-FabShrink and Stretch up to 14-gauge Mild Steel with the WFSS14 Weighing in at 200lbs, set on a sturdy frame with an easy to use kick pedal, the WFSS1...

View full detailsBaileigh MSS-18 Shrinker Stretcher Pair

BaileighComplete Entry Level Shrinker Stretcher Setup The MSS-18 Shrinker Stretcher Combo from Baileigh is the perfect combination for those looking to set...

View full detailsJS Tools KSM155 Pro Deep Throat Shrinker/Stretcher

JS Tools5.0 / 5.0

1 Review

KSM155 Pro Shrinker / Stretcher for the discerning craftsmen The JS Tools KSM155 Pro Deep Throat Shrinker / Stretcher is a professional quality too...

View full detailsWoodward-Fab WFSSDF Foot Operated Shrinker Stretcher Combo

Woodward-FabShrink and Stretch with ease with the Woodward Fab WFSSDF Combining both a shrinker and separate stretcher on a handy foot operated stand which mak...

View full detailsMittler Bros. Shrinker Stretcher combo with Foot Operation Stand

Mittler Bros.Genuine Lancaster Shrinker Stretchers on Foot Operation Stand This pair of genuine Lancaster Shrinker Stretchers comes on an easy to use Foot Opera...

View full detailsBaileigh MSS-14F Foot Operated Shrinker Stretcher

BaileighMSS-14F | Shrink and Stretch 16 Gauge Steel! If you work with thicker steel on a regular basis then this is the Shrinker / Stretcher for you - with...

View full detailsWoodward-Fab WFSSCAST9 Heavy Cast Iron Deep Throat Shrinker Stretcher with Foot Operated Stand

Woodward-FabRigid and durable Cast Iron frame The WFSSCAST9 Heavy Cast Iron Deep Throat Shrinker Stretcher from Woodward-Fab features a heavy cast iron frame o...

View full detailsErco 1447 Shrinker Stretcher

ErcoErco 1447-6DT - 6" Throat Depth Kick Shrinker Stretcher With a heavy-duty cast iron C frame providing a 6" throat depth and interchangeable jaws, t...

View full detailsWoodward-Fab Portable Handheld Shrinker Stretcher (WFSS10P)

Woodward-FabShrink and Stretch Panels in-situ with the WFSS10P Handheld Shrinker Stretcher The WFSS10P from Woodward-Fab is a portable, handheld shrinker stret...

View full detailsEckold HF 100 Shrinker Stretcher

EckoldEckold HF 100 - Shrink, Stretch and More A shrinker and stretcher at heart, the Eckold Handformer HF100 is so much more. With its intuitive quick-c...

View full detailsBaileigh MSS-16F

BaileighShrink and Stretch Without the Marring - Baileigh MSS-16F The MSS-16F From Baileigh Industrial uses jaws with rounded edges to minimize the marking...

View full detailsMittler Bros. Shrinker / Stretcher Pair (550-STSH)

Mittler Bros.Get a pair of USA made Lancaster Shrinker Stretchers This pair of genuine Lancaster Shrinker Stretchers is made to the highest standards in the USA...

View full detailsBaileigh MSS-16 Shrinker Stretcher

BaileighLooking for a Shrinker / Stretcher with the throat depth to get deep into panels? The Baileigh MSS-16 Shrinker Stretcher has a 8in throat depth let...

View full detailsWoodward-Fab WFSS10 Shrinker Stretcher

Woodward-FabCompact uni-body shrinker stretcher with flexible mounting options The WFSS10 Shrinker Stretcher from Woodward-Fab is a small form uni-body machine...

View full detailsWoodward-Fab WFSS10-DEEP Deep Throat Shrinker Stretcher

Woodward-FabCost effective 8" deep throat shrinker stretcher The Woodward-Fab Deep Throat Shrinker Stretcher offers an impressive 8inch throat depth to accomm...

View full details